Pipe Discharge

The valves in the range are hygienic equipment intended to protect tanks against vacuums (vacuum breaker) and/or excess pressure. They are fitted with a technical tube (washing function, sterile air intake). The pressurised function blow-off is collected. The passage sections, different for pressure and vacuum, are specifically designed to protect the tanks against sudden temperature variations resulting from hot washing (and SIP) followed by a cold rinse.

Possesses design tools to dimension a valve with respect to tank characteristics (diameter, height), resistance (pressure and vacuum) and washing conditions (temperature, flow-rate).

Key Benefits:

1、Valve certified 3A & FDA

2、Combined pressure and vacuum

3、SIP & CIP connection port

4、Control unit

5、Sterile air connection

6、Specially designed for protection against thermal shocks (hot/cold washes)

7、Fully autonomous (no external control required for its operation)

8、Hygienic design

9、Simplified and cost-effective maintenance (with no lifting or special tools)

10、Numerous options available according to requirements

Vacuum Relief Valves / Vacuum and Pressure Relief Valves

Atmospheric Discharge

Valves for safeguarding against excess vacuums and pressures in pressure vessels and pipelines.

The valve position signal output for sensor option

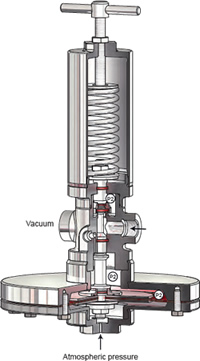

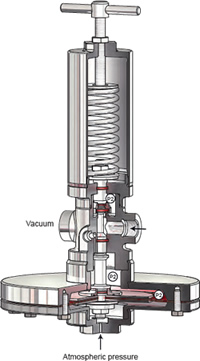

Vacuum Control Valves

Vacuum Control Valves

Vacuum Control Valves for industrial, foodstuffs and pharmaceutical plant are either piston or membrane controlled proportional valves with spring loading, depending upon the vacuum range.

They are used to keep the vacuum pressure P2 at a constant adjustable reference value with fluctuating flow volumes.

Vacuum controllers are special design differential pressure control valves with an opening function.

Nominal pressures : PN 1.6 to PN 16

Connections : G 1/4 to G 2 ½ or DN 10 to DN 80

Process connections : normal commercial thread, screw, clamp or

flange connections

Materials : 1.4301, 1.4571, 1.4404, 1.4435, as well as

elastomer and thermo-plastic element seals

Kvs values : 1.2 to 28.5 m3/h

Primary pressure ranges P2 : -0.005 bars to -0.95 bars

Flow mediums : gases, steam

Vacuum and Pressure Relief Valve Mounting and Application